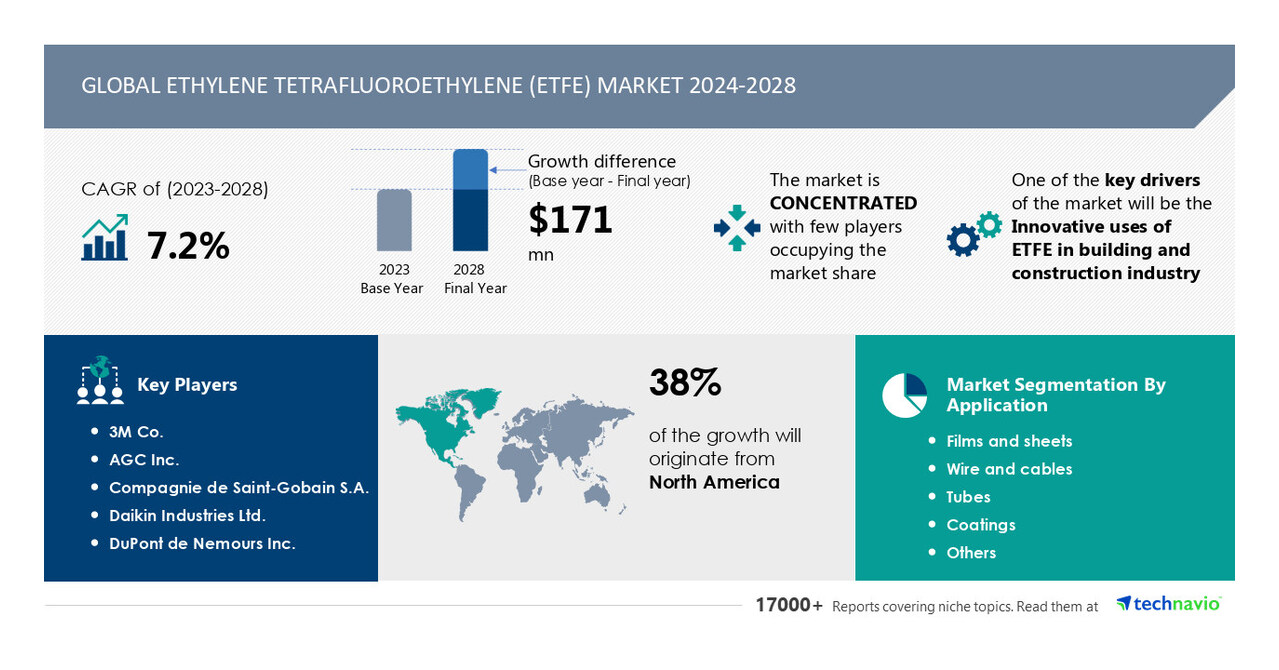

NEW YORK, Nov. 6, 2024 /PRNewswire/ — Report with the AI impact on market trends – The global ethylene tetrafluoroethylene (ETFE) market size is estimated to grow by USD 171 million from 2024-2028, according to Technavio. The market is estimated to grow at a CAGR of 7.2% during the forecast period. Innovative uses of ETFE in building and construction industry is driving market growth, with a trend towards advantages of ETFE films in greenhouses. However, risks involved during handling of etfe resins poses a challenge.Key market players include 3M Co., AGC Inc., Compagnie de Saint-Gobain S.A., Daikin Industries Ltd., DuPont de Nemours Inc., HaloPolymer OJSC, Hubei Everflon Polymer Co. Ltd., Mitsubishi Chemical Corp., Solvay SA, The Chemours Co., Vector Foiltec, and Zeus Co. Inc..

AI-Powered Market Evolution Insights. Our comprehensive market report ready with the latest trends, growth opportunities, and strategic analysis- View Free Sample Report PDF

|

Forecast period |

2024-2028 |

|

Base Year |

2023 |

|

Historic Data |

2018 – 2022 |

|

Segment Covered |

Application (Films and sheets, Wire and cables, Tubes, Coatings, and Others) and Geography (North America, APAC, Europe, Middle East and Africa, and South America) |

|

Region Covered |

North America, APAC, Europe, Middle East and Africa, and South America |

|

Key companies profiled |

3M Co., AGC Inc., Compagnie de Saint-Gobain S.A., Daikin Industries Ltd., DuPont de Nemours Inc., HaloPolymer OJSC, Hubei Everflon Polymer Co. Ltd., Mitsubishi Chemical Corp., Solvay SA, The Chemours Co., Vector Foiltec, and Zeus Co. Inc. |

Key Market Trends Fueling Growth

Ethylene Tetrafluoroethylene (ETFE) films have gained popularity in the greenhouse industry due to their durability and superior light transmission properties. Compared to traditional coverings like glass, ETFE is lighter in weight yet offers higher UV transmission rates. ETFE films have lower reflection and refraction rates, maximizing the use of available light. Available in various shades and types, these films cater to the specific light requirements of high-value crops such as flowering plants and those requiring anthocyanins. ETFE films boast low surface energy properties, making them resistant to chemicals, harsh weather, bacteria, and molds. Their non-stick surface keeps the greenhouse exterior clean. ETFE films prevent condensation and have a long service life of over 30 years, even in extreme temperatures. Leading vendors like AGC Inc. Provide ETFE films under the F-CLEAN brand, available in thicknesses from 60 um to 100 um and in clear, diffused, and soft shine series. Clear ETFE films offer full sunlight spectrum, while diffused films eliminate shadows and soft shine films transmit 14% light, preventing heat build-up. The benefits of ETFE films contribute to their increasing adoption in horticulture, driving the global ETFE market growth.

Ethylene Tetrafluoroethylene (ETFE) is a high-performance fluoropolymer gaining significant traction in various industries. The market for ETFE is on an upward trend due to its extensive applications in Solar Panels, Building and Construction, Aerospace and Defence, Nuclear, Electronics, and Manufacturing Facilities. In Solar Panels, ETFE offers thermal flexibility and chemical resistance for photovoltaic applications. For Building and Construction, ETFE provides lightweight materials with excellent mechanical properties, UV exposure resistance, and sound transmission properties. In Aerospace, ETFE’s lightweight and corrosion-resistant features make it ideal for manufacturing facilities and tensile structures. ETFE films and sheets offer energy efficiency, sustainability, and recyclability for net-zero emissions projects. With its durability, high abrasion resistance, and chemical resistance, ETFE is a popular choice for electrical coatings and various industrial applications. The market for ETFE pellets or granules, powder, and transparent barrier films is expected to grow in the fields of renewable energy, green buildings, and environmentally friendly materials. Extrusion molding and injection molding processes are commonly used for producing ETFE products.

Insights on how AI is driving innovation, efficiency, and market growth- Request Sample!

Market Challenges

- The Ethylene Tetrafluoroethylene (ETFE) market faces challenges due to the risks associated with handling and processing ETFE resins. Workers may be exposed to harmful decomposition products when ETFE is heated above 200-to-260-degrees Celsius. Inhalation of these fumes should be avoided to prevent health hazards. Containers should be opened in well-ventilated areas with local exhaust ventilation. Hot processing vapors and fumes must be exhausted completely from the work area. Workers should avoid contaminating tobacco with ETFE and smoking tobacco or cigarettes contaminated with ETFE can cause flu-like symptoms. Mixing ETFE with finely divided metals like magnesium or aluminum can be flammable or explosive. Trade associations provide guidelines for safe handling of fluoropolymer resins, including ETFE resins. Vendors must ensure proper ventilation in process equipment and work areas to prevent fume inhalation, mitigating potential risks to worker health and market growth during the forecast period.

- The ETFE market is driven by the demand for high-performance materials in various industries. EtFE offers exceptional properties such as high abrasion resistance, chemical resistance, and mechanical strength, making it ideal for use in renewable energy and solar energy applications. In the context of reducing greenhouse gas emissions, EtFE’s thermal stability and electrical properties make it a popular choice for coating applications, particularly in aerospace, defense, and public infrastructure. Moreover, EtFE’s durability and weatherability make it suitable for construction applications, and its radiation resistance and use in fiber-reinforced plastics make it a preferred material in the chemicals industry. EtFE’s lightweight and high light transmittance properties make it a popular choice for sustainable buildings and electrical applications, including wires and cables, tubes, and transparent barrier films. The circular economy is a growing trend in the EtFE market, with an increasing focus on pellets or granules and powder forms of the material. The market also offers opportunities in extrusion molding and injection molding processes, providing solutions for various industries, including coatings, automotive, and packaging.

Insights into how AI is reshaping industries and driving growth- Download a Sample Report

Segment Overview

This ethylene tetrafluoroethylene (etfe) market report extensively covers market segmentation by

- Application

- 1.1 Films and sheets

- 1.2 Wire and cables

- 1.3 Tubes

- 1.4 Coatings

- 1.5 Others

- 2.1 North America

- 2.2 APAC

- 2.3 Europe

- 2.4 Middle East and Africa

- 2.5 South America

1.1 Films and sheets- ETFE, or Ethylene Tetrafluoroethylene, is a resin offering superior chemical and electrical properties compared to other alternatives. Its mechanical ruggedness and easy, economical processing make it an attractive choice for design engineers in various industries. ETFE is used in the form of granular material to manufacture films and sheets, which can be heat-sealed, thermoformed, welded, heat-laminated, and coated. ETFE films and sheets have applications in building and construction, where they offer light transmission properties as an alternative to glass. For instance, Textiles Coated International’s Reveal ETFE films are used for architectural and greenhouse applications due to their lightweight nature, weighing only 1% of the equivalent glass amount. ETFE sheets can be inflated for thermal insulation and structural applications. In the pharmaceutical industry, ETFE films are used for vial cap liners, septa, stoppers, sampling bags, flexible culture bags, blood storage bags, 2-D fluid bags, and storage or transportation containers. These films are chemically inert, have a long shelf life, and offer high purity without additives. The solar industry benefits from ETFE films due to their high solar transmission, heat resistance, UV resistance, and outdoor durability. They are used as external materials for the front and back sheets of flexible photovoltaic panels and the glazing of solar collectors, protecting panels from harsh environments. Solar cells made from ETFE films are lightweight, cost-effective, less rigid, and highly durable compared to traditional glass. In summary, ETFE films and sheets provide various industries with high-performance solutions for design engineers, offering superior properties, ease of processing, and a wide range of applications. These include the building and construction, pharmaceutical, and solar industries, where ETFE’s lightweight, durable, and chemically inert properties make it a valuable alternative to traditional materials.

Download complimentary Sample Report to gain insights into AI’s impact on market dynamics, emerging trends, and future opportunities- including forecast (2024-2028) and historic data (2018 – 2022)

Research Analysis

Ethylene Tetrafluoroethylene (ETFE) is a versatile fluoropolymer with unique properties, making it an essential material in various industries. ETFE is known for its excellent chemical resistance, durability, weatherability, and mechanical strength. In the solar panel industry, ETFE is used as a protective layer due to its excellent optical clarity and resistance to UV radiation. In building and construction, ETFE is utilized in the production of green buildings and infrastructure development projects for its lightweight, corrosion-resistant, and environmentally friendly properties. The aerospace and defense sectors benefit from ETFE’s high abrasion resistance, radiation resistance, and chemical resistance. In the nuclear industry, ETFE is used in the production of pipes and vessels due to its resistance to harsh chemicals and high temperatures. ETFE is also used in the electronics industry for its electrical insulation properties and in the manufacturing of fiber-reinforced plastics. The material’s durability, weatherability, and chemical resistance make it an ideal choice for electrical coatings and various construction applications. Overall, Ethylene Tetrafluoroethylene is a valuable material in various industries due to its unique properties and ability to reduce greenhouse gas emissions.

Market Research Overview

Ethylene Tetrafluoroethylene (ETFE) is a versatile fluoropolymer used in various industries due to its exceptional properties. In the realm of renewable energy, ETFE plays a significant role in solar panels, offering thermal flexibility and mechanical strength. In building and construction, ETFE is utilized for its lightweight, corrosion-resistant, and UV exposure-resistant films and sheets, contributing to net-zero emissions, energy efficiency, and sustainability in green buildings. ETFE’s properties extend to aerospace and defense, where its lightweight, high abrasion resistance, and chemical resistance are essential. In the nuclear industry, ETFE’s radiation resistance and durability make it a preferred choice for various applications. In electronics, ETFE pellets or granules are used for manufacturing facilities due to their excellent mechanical properties, chemical flexibility, and electrical insulation. ETFE films and sheets are also used in photovoltaic applications for their transparency and thermal stability. ETFE’s properties also cater to various industries, including chemicals, where it’s used in fiber-reinforced plastics and coatings. Its mechanical strength, chemical resistance, and weatherability make it an ideal choice for various applications, including wires and cables, tubes, and extrusion and injection molding processes. ETFE’s circular economy approach, recyclability, and environmental friendliness make it a popular choice for various industries, contributing to a sustainable future.

Table of Contents:

1 Executive Summary

2 Market Landscape

3 Market Sizing

4 Historic Market Size

5 Five Forces Analysis

6 Market Segmentation

- Application

- Films And Sheets

- Wire And Cables

- Tubes

- Coatings

- Others

- Geography

- North America

- APAC

- Europe

- Middle East And Africa

- South America

7 Customer Landscape

8 Geographic Landscape

9 Drivers, Challenges, and Trends

10 Company Landscape

11 Company Analysis

12 Appendix

About Technavio

Technavio is a leading global technology research and advisory company. Their research and analysis focuses on emerging market trends and provides actionable insights to help businesses identify market opportunities and develop effective strategies to optimize their market positions.

With over 500 specialized analysts, Technavio’s report library consists of more than 17,000 reports and counting, covering 800 technologies, spanning across 50 countries. Their client base consists of enterprises of all sizes, including more than 100 Fortune 500 companies. This growing client base relies on Technavio’s comprehensive coverage, extensive research, and actionable market insights to identify opportunities in existing and potential markets and assess their competitive positions within changing market scenarios.

Contacts

Technavio Research

Jesse Maida

Media & Marketing Executive

US: +1 844 364 1100

UK: +44 203 893 3200

Email: [email protected]

Website: www.technavio.com/

SOURCE Technavio

WANT YOUR COMPANY’S NEWS FEATURED ON PRNEWSWIRE.COM?

440k+

Newsrooms &

Influencers

9k+

Digital Media

Outlets

270k+

Journalists

Opted In