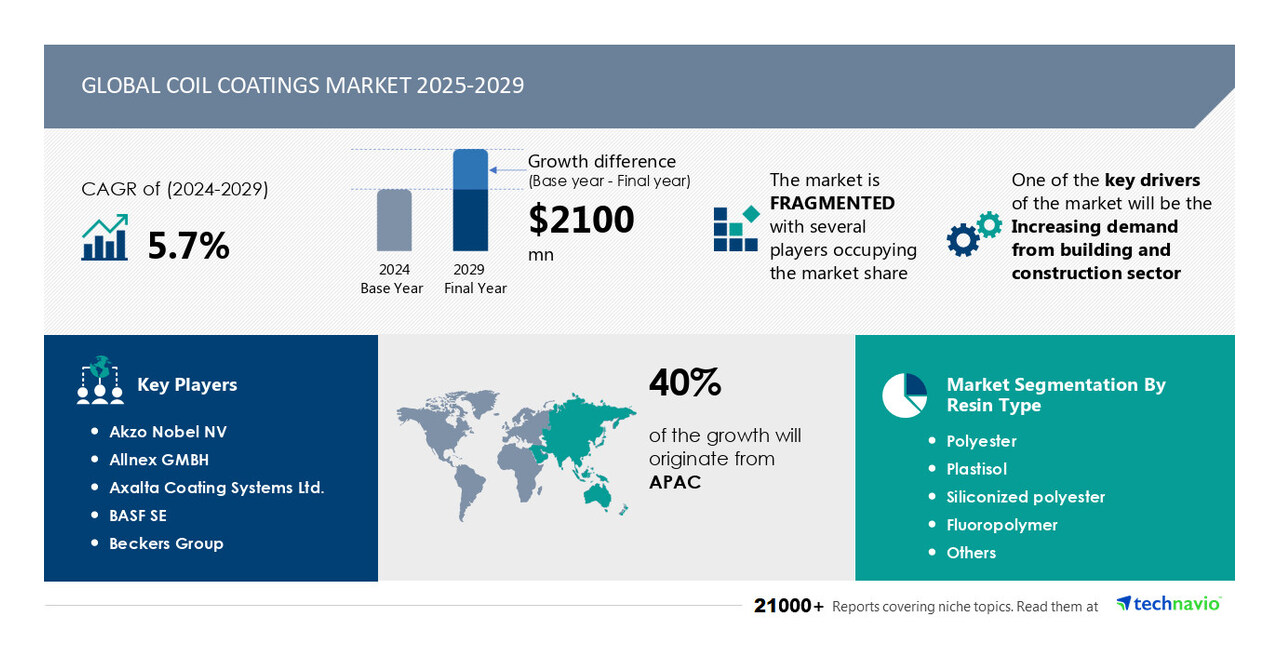

NEW YORK, Jan. 30, 2025 /PRNewswire/ — Report on how AI is driving market transformation – The global coil coatings market size is estimated to grow by USD 2.1 billion from 2025-2029, according to Technavio. The market is estimated to grow at a CAGR of 5.7% during the forecast period. Increasing demand from building and construction sector is driving market growth, with a trend towards increasing number of mergers and acquisitions among vendors. However, volatility in raw material prices of coil coatings poses a challenge. Key market players include Akzo Nobel NV, Allnex GMBH, Axalta Coating Systems Ltd., BASF SE, Beckers Group, BlueScope Steel Ltd., Bulk Chemicals Inc., Cabot Corp., Covestro AG, Englert Inc., Euramax, Henkel AG and Co. KGaA, Kansai Paint Co. Ltd., Material Sciences Corp., Nippon Paint Holdings Co. Ltd., Northern Coatings and Chemical Co., PPG Industries Inc., Salchi Metalcoat Srl, The Sherwin Williams Co., and Wacker Chemie AG.

Key insights into market evolution with AI-powered analysis. Explore trends, segmentation, and growth drivers- View Free Sample PDF

|

Coil Coatings Market Scope |

|

|

Report Coverage |

Details |

|

Base year |

2024 |

|

Historic period |

2019 – 2023 |

|

Forecast period |

2025-2029 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 5.7% |

|

Market growth 2025-2029 |

USD 2100 million |

|

Market structure |

Fragmented |

|

YoY growth 2022-2023 (%) |

5.1 |

|

Regional analysis |

APAC, North America, Europe, Middle East and Africa, and South America |

|

Performing market contribution |

APAC at 40% |

|

Key countries |

US, China, Germany, UK, Japan, India, France, South Korea, Canada, and Italy |

|

Key companies profiled |

Akzo Nobel NV, Allnex GMBH, Axalta Coating Systems Ltd., BASF SE, Beckers Group, BlueScope Steel Ltd., Bulk Chemicals Inc., Cabot Corp., Covestro AG, Englert Inc., Euramax, Henkel AG and Co. KGaA, Kansai Paint Co. Ltd., Material Sciences Corp., Nippon Paint Holdings Co. Ltd., Northern Coatings and Chemical Co., PPG Industries Inc., Salchi Metalcoat Srl, The Sherwin Williams Co., and Wacker Chemie AG |

Market Driver

The Coil Coatings Market is experiencing significant trends in the industrial sector, particularly in the use of paint for metal surfaces in infrastructure projects. Technological advancements in high-performance polymer coatings offer superior corrosion resistance and UV radiation protection for steel structures, including industrial facilities, cladding, and roofing. Consumer preferences for environmentally friendly solutions have led to the development of alternative products and recycling programs. Coil coatings are increasingly being used in harsh weather conditions for applications such as pre-painted steel and coated steel in building and construction, automotive, and appliance industries. Legislation and statutory regulations are driving the adoption of low-VOC content coating formulations and sustainable coating solutions. Innovation in coil coating technologies includes water-based formulations, which offer energy savings and reduced VOC emissions. Coil coating application processes have improved efficiency and reduced toxic substance usage. Industries using coil coatings include federal agencies, automakers, and manufacturers of reactors, armatures, transformers, pipelines, and composite panels. Coil coatings provide a superior quality finish, longer lifespan, and aesthetics for various applications, including wall cladding and metal roofing. Superior surface chemistry ensures color-coated coils maintain their vibrant colors and resist fading. Coil coating solutions offer energy savings, insulation, and compliance with building codes and sustainability goals.

The coil coatings market is witnessing significant growth strategies from key players to expand their product offerings and increase market shares. Acquisitions, partnerships, and collaborations are popular strategies to broaden the portfolio and cater to various end-user industries, including automotive, building and construction, and appliances. BlueScope’s recent acquisition of Cornerstone Building Brands’ coil coatings business is an example of this trend. Such moves strengthen companies’ positions in the global coil coatings market and enhance their ability to serve diverse customer needs.

Request Sample of our comprehensive report now to stay ahead in the AI-driven market evolution!

Market Challenges

- The Coil Coatings Market faces several challenges in the paint industry. Industrial facilities require high-performance polymer coatings for metal surfaces, such as steel, to withstand harsh weather conditions and UV radiation. However, there is a growing demand for environmentally friendly solutions, including alternative products with low-VOC content and recycling programs. Legislation and statutory regulations, including federal agencies and environmental regulations, also impact the market. Technological advancements in sustainable coating formulations, such as water-based formulations, are essential to meet sustainability goals and consumer preferences. Coil coatings are used in various industries, including automakers, home appliances, and infrastructure, for cladding, insulation, and corrosion resistance. Innovation in processes and surface chemistry is crucial to ensure superior quality finishes, longevity, and aesthetics. Coil coating solutions are essential for pre-painted steel and coated steel in roofing, wall cladding, and other applications. Coil coating application is also critical for reactors, armatures, transformers, pipelines, and metal roofing to enhance energy savings and meet building codes.

- Coil coatings are manufactured using binders and solvents, including metals, alcohols, and resins. Resins serve as the fundamental raw materials for producing binders. The cost of coil coatings is directly influenced by the price fluctuations of these raw materials. Vendors are forced to increase the final product price when raw material costs rise. Factors such as high demand-to-supply ratios, taxes, duties, tariffs, and production disruptions in iron ore mining can lead to increased raw material prices. To maintain price and product mix control, key players procure raw materials prior to production.

Discover how AI is revolutionizing market trends- Get your access now!

Segment Overview

This coil coatings market report extensively covers market segmentation by

- Resin Type

- 1.1 Polyester

- 1.2 Plastisol

- 1.3 Siliconized polyester

- 1.4 Fluoropolymer

- 1.5 Others

- 2.1 Building and construction

- 2.2 Automotive

- 2.3 Appliances

- 2.4 Others

- 3.1 APAC

- 3.2 North America

- 3.3 Europe

- 3.4 Middle East and Africa

- 3.5 South America

1.1 Polyester- Coil coatings are an essential part of various industries, including construction, automotive, and aerospace. The majority of resins used in coil coating applications are linear polyesters, which offer better metal adhesion and impact resistance than thermosetting acrylics. These polyesters can be engineered to provide excellent mechanical, impact, UV, and chemical resistance in waterborne, high solids, low-VOC, and powder coatings. The most common type of polyester polyol used for coil coatings is hydroxyl-terminated linear polyester polyols. These polymers are preferred for their flexibility and chemical resistance when cured with melamine or blocked isocyanate. Coil coatings are applied to metal coils after they are formed, a process known as pre-paint. Linear polyesters used in coil coatings typically employ diols like neopentyl glycol, propylene glycol, butane diol, or 1,6 hexane diols instead of trifunctional hydroxyl building blocks. The diacids of these resins can be a mixture of an aromatic diacid and a linear aliphatic diacid or a dianhydride of the latter. Coil coatings are cured quickly at high temperatures using an aminoplast crosslinker such as melamine or a blocked isocyanate. The increasing demand for coil coatings is driving the growth of the polyester segment in the global coil coatings market due to their superior properties and versatility.

Download a Sample of our comprehensive report today to discover how AI-driven innovations are reshaping competitive dynamics

Research Analysis

The coil coating market refers to the production and application of thin, uniform films of protective and decorative coatings on steel and aluminum coils. These prepainted metal panels are widely used in various industries, including construction, automotive, and appliance manufacturing. Coil coating materials are essential for this process, with key considerations including coating thickness, durability, and resistance to weathering and chemicals. Coil coating services and suppliers play a crucial role in the industry, providing expertise in application techniques and supplying a range of coating options. Coil coating manufacturers continually innovate to meet evolving market demands, incorporating advanced technologies and sustainable practices. Government agencies set regulations to ensure coil coating safety and environmental sustainability. Coil coating technology has evolved to offer benefits such as flexibility, hardness, and improved performance. Applications for coil coating span across industries, with architectural and aluminum coil coatings being popular choices for their aesthetic appeal and durability. Coil coating development focuses on enhancing coating resistance, increasing sustainability, and improving the coating process efficiency. Coil coating standards ensure consistent quality and performance, while coil coating innovation continues to push the boundaries of what is possible in this versatile industry.

Market Research Overview

The coil coating market encompasses high-performance polymer coatings applied to industrial facilities and various products, including metal, cladding, steel, and pre-painted steel. Technological advancements in this industry have led to the development of UV radiation-resistant coatings, alternative products, and environmentally friendly solutions. Infrastructure projects, such as buildings, bridges, and energy infrastructure, increasingly rely on coil coatings for corrosion resistance and energy savings. Harsh weather conditions, including UV rays and extreme temperatures, necessitate the use of superior quality finish coatings. Consumer preferences for sustainable coating formulations, such as water-based and low-VOC content, are driving innovation in the market. Statutory regulations and legislations, including those related to VOC emissions and toxic substances, are also influencing the market. Applications of coil coatings span across various industries, including automakers, home appliances, and federal agencies, for roofing, wall cladding, insulation, and more. Coil coating solutions offer energy savings, longer lifespan, and superior aesthetics, making them a popular choice for designers and consumers alike. Processes like reactors, armatures, transformers, pipelines, and metal roofing benefit from the efficiency and durability of coil coatings. Building codes and sustainability goals continue to push the industry towards innovation in coil coating technologies.

Table of Contents:

1 Executive Summary

2 Market Landscape

3 Market Sizing

4 Historic Market Size

5 Five Forces Analysis

6 Market Segmentation

- Resin Type

- Polyester

- Plastisol

- Siliconized Polyester

- Fluoropolymer

- Others

- End-user

- Building And Construction

- Automotive

- Appliances

- Others

- Geography

- APAC

- North America

- Europe

- Middle East And Africa

- South America

7 Customer Landscape

8 Geographic Landscape

9 Drivers, Challenges, and Trends

10 Company Landscape

11 Company Analysis

12 Appendix

About Technavio

Technavio is a leading global technology research and advisory company. Their research and analysis focuses on emerging market trends and provides actionable insights to help businesses identify market opportunities and develop effective strategies to optimize their market positions.

With over 500 specialized analysts, Technavio’s report library consists of more than 17,000 reports and counting, covering 800 technologies, spanning across 50 countries. Their client base consists of enterprises of all sizes, including more than 100 Fortune 500 companies. This growing client base relies on Technavio’s comprehensive coverage, extensive research, and actionable market insights to identify opportunities in existing and potential markets and assess their competitive positions within changing market scenarios.

Contacts

Technavio Research

Jesse Maida

Media & Marketing Executive

US: +1 844 364 1100

UK: +44 203 893 3200

Email: [email protected]

Website: www.technavio.com/

SOURCE Technavio